Trusted process

Trusted process

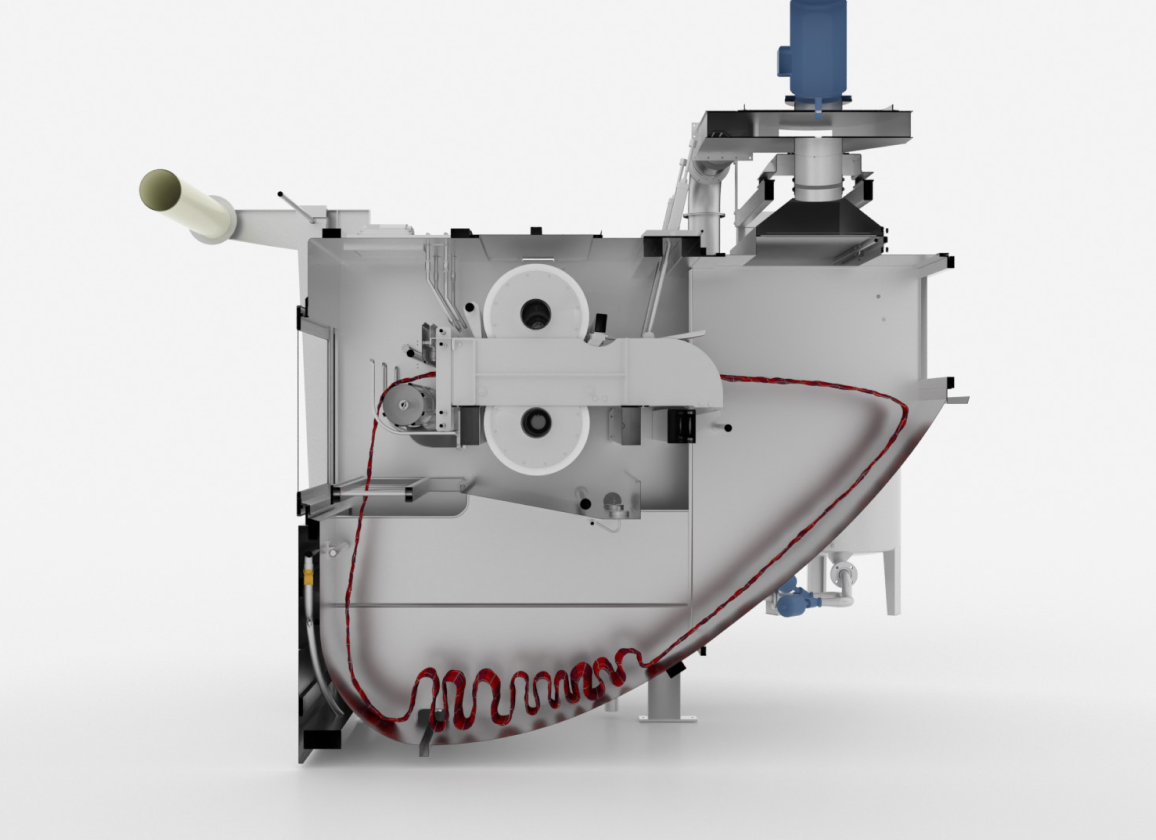

Combined washing and milling machine for woollen fabrics

Biancalani MILLA, the state-of-the-art solution for washing and milling of any type of woollen fabric.

Here’s MILLA

Coming from the tradition of quality and the expertise of Biancalani, MILLA is the state-of-the-art solution for combined washing and milling of any type of woollen fabric. Pure-wool or blended, carded or combed, woven or knitted: MILLA is designed for optimal performances ensuring thorough and deep milling on heavy fabrics, and a safe action on lightweight articles, for perfect results, always.

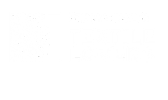

Four washing and milling channel

Combining a clean and efficient design with innovative technological solutions, MILLA is able to meet the requirements of a modern wool-processing plant, by reliably delivering consistent results, matching high productivity with flexibility and ease of use and maintenance.

Smart design for high productivity

The special design of the self-supporting body, entirely in stainless steel, guarantees a high loading capacity, as well as toughness and durability, with a compact form factor.

The pressure of the milling box plates can be set independently for each channel, and a pneumatic lightening device for the upper cylinder, together with special grooved synthetic rubber covering of the cylinders, ensures complete safety of the process.

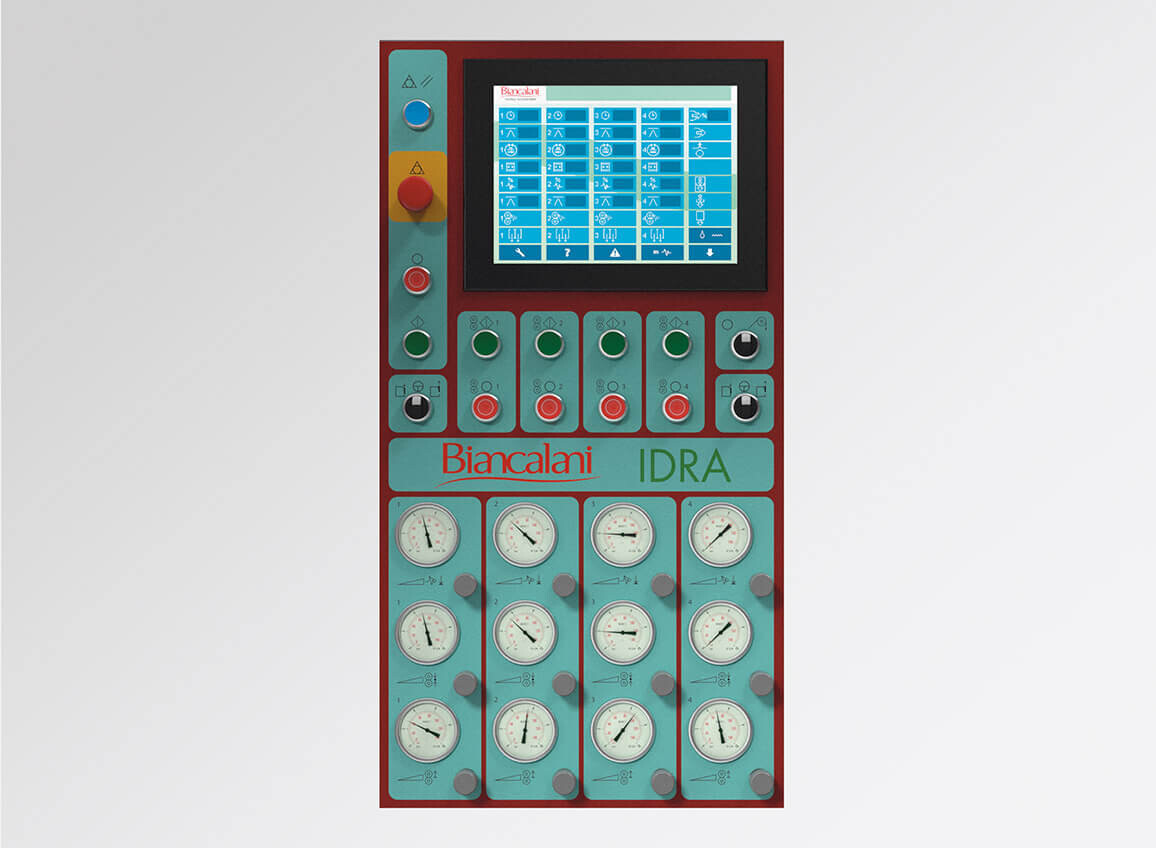

Ease of use and maintenance

All the operational parameters are monitored and easily managed through an integrated touch-screen display connected with the PLC, which also controls the automatic introduction of chemical products from the external tank.

Wide front opening for loading and unloading operations and full rear access allow users to easily inspect the machine and simplify the maintenance operations.

Applications and processes

MILLA can be used to obtain perfect washing and milling results on any kind of woollen and wool-blended fabric, in weights ranging from 100 to 1200 grams per metre, woven and knitted, carded and combed, for a really wide range of applications, from men's and women's apparel, to automotive, home textile, and special-purpose materials (billiards table cloth, tennis balls…).

Technical specifications

Number of channels | 4 |

Loading capacity | 150 Kg/channel |

Treatment speed | 25-500 m/min |

Distance between fabric | 50-170 mm |

Capacity of tank for chemical | 600 L |

Maximum water capacity of the vat | 2500 L |

Maximum water temperature | 60° C |

Installed electrical power | 70 kW |

Average absorbed electrical power | 49 kW |

Dimensions (W x L x H) | 4650 x 4700 x 3450 mm |

Depth of foundation | 600 mm |

Weight | 9000 Kg |

*The data shown can be changed at any time without prior notice due to product modification and improvement | |

Download brochure

CONTACT & SUPPORT

Write us to get more information or to request a test on your fabrics.

WHY CHOOSE US

At Biancalani we do a lot more for you than just building machines. We listen to your advice and desires and make it easy for you to reach your goals offering you our past as a present: we strive to be part of your future.