All in one solution

All in one solution

All-in-one preparation and finishing

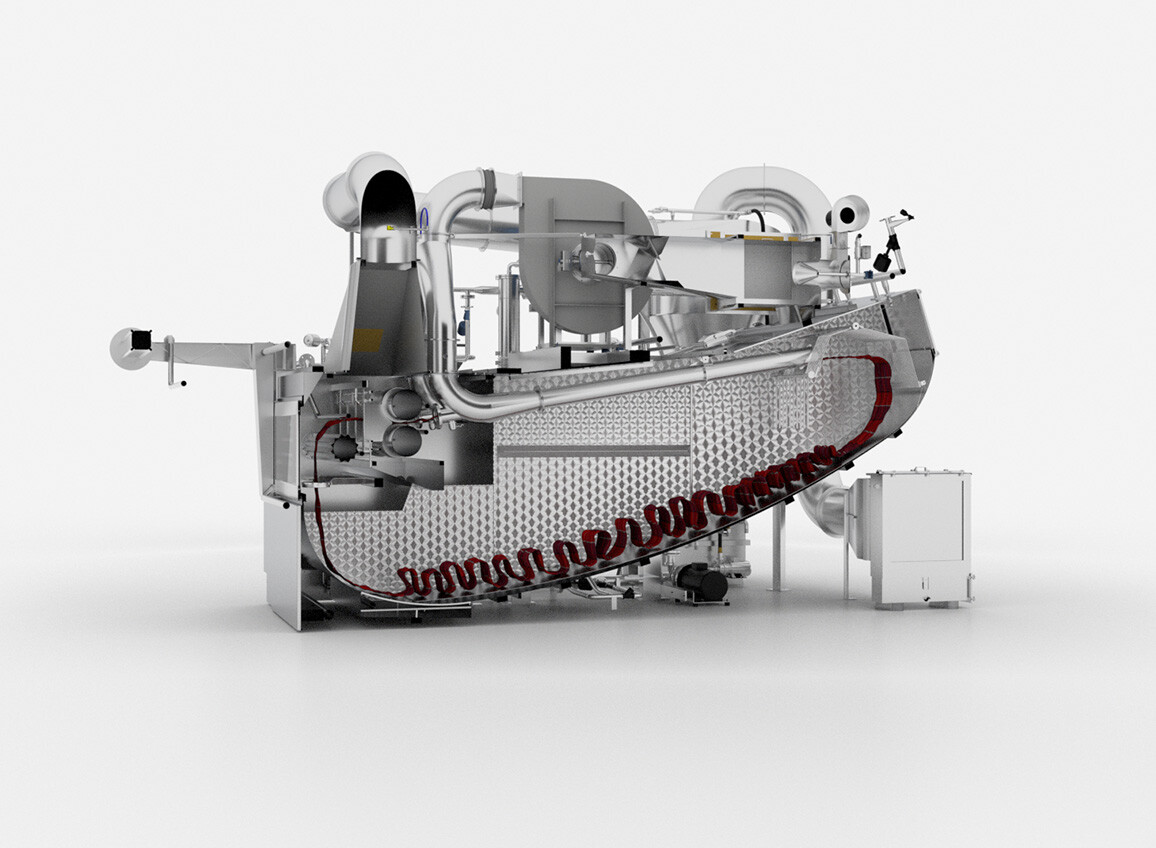

Biancalani AIRO®, the all-round finishing machine for washing, drying and softening any kind of woven, non-woven and knitted fabric. A high quality finishing style which has no equal in the world. The AIRO®style.

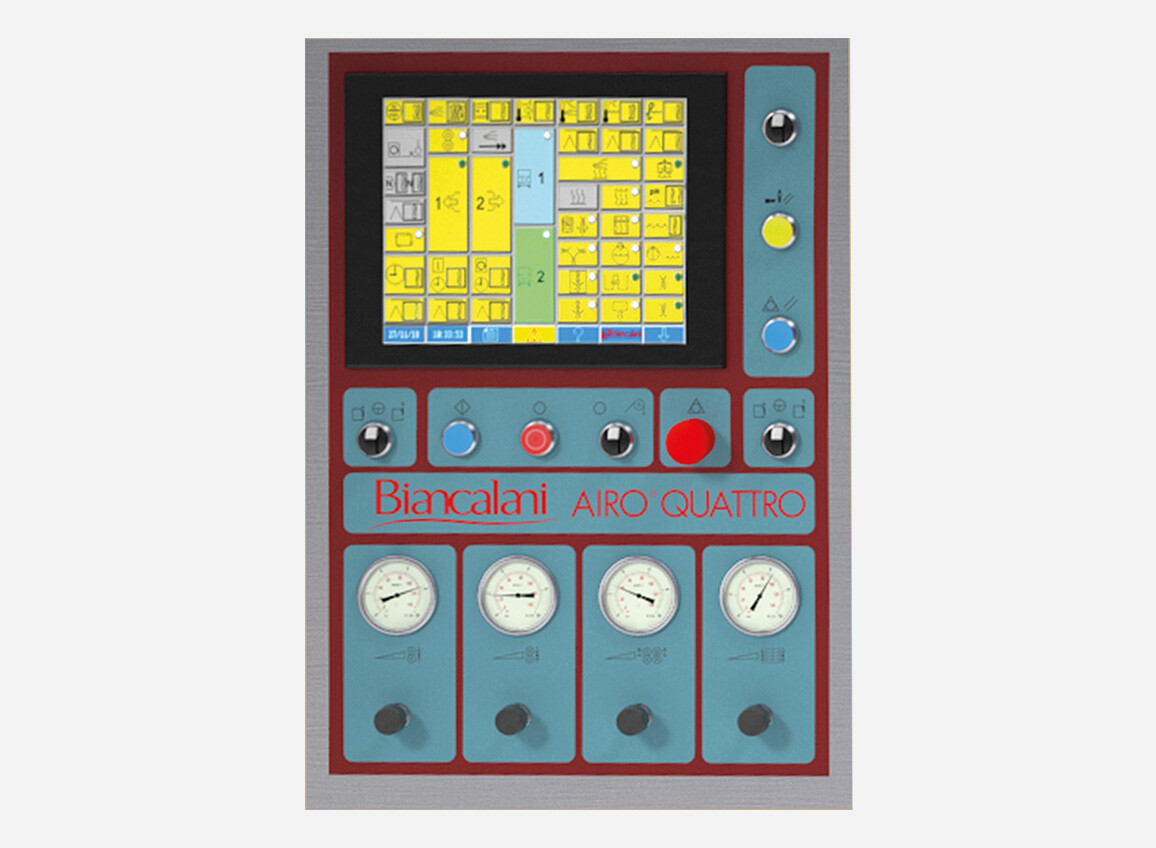

Two or four channels

Washing & drying or drying only

Up to 1000 metres per minute

Up to 450 kg per hour

Here’s how it works

The AIRO® principle, introduced and patented in 1985 by Biancalani, is based on the combination of an air-only fabric transport system and the high-speed impact of the material against a special stainless steel grill. The fabric is driven by an intense airflow and accelerated without any tension inside the processing tubes. It is then ejected against an impact grid positioned at the rear of the machine, where it discharges all the accumulated kinetic energy. After falling onto a Teflon-coated slide, the fabric flows to the front of the treatment vat, ready to be guided by a roller to the beginning of a new cycle.

Feel the power of air and steel

The exclusive air-only transport system keeps the fabric safe from any form of mechanical crease or abrasion. It delivers a strong and delicate action during the washing or squeezing process without any friction and with absolute absence of defects, as the fabric is continuously “massaged” by air inside the tubes and immediately opened as soon as it is ejected at high speed toward the stainless steel impact grill. At the same time, the air forces the water to deeply penetrate the fabric, while the impact against the grill quickly discharges it, largely improving the efficiency of the washing process, and providing a mechanical and permanent effect of softening and natural compaction of the fibers, universally known as AIRO® Hand.

Suitable for every fabric

AIRO® can process any type of textile surface in a very wide range of compositions, always with optimal results. From natural fibres and blends, to artificial (viscose, polyammide, cupro, lyocell, modal) and synthetic ones, woven, knitted, non-woven, coated, or laminated, for different applications ranging from apparel to upholstery to home textile and technical applications. There are no limits in terms of weight and width. Results are obtained in complete safety and without defects.

What can AIRO® do for you?

On all versions:

- Airflow tumble-drying and mechanical softening of wet fabric

- Mechanical, chemical-free softening, on dry fabric or with steam application

- Mechanical softening after application of chemical products

- Intensive steaming treatments

- Single-pass polymerization and softening of resin-treated fabric

- Cleaning treatment after bio-polishing and surface finishing

- Compaction, stabilization, relax

Additionally, on AIRO® versions with washing capabilities:

- Application of chemicals (i.e. softener) by exhaustion

- Fibrillation and defibrillation

- Bio-polishing and enzyme washing treatments

- Light milling of woollen fabrics

- Washing, desizing, scouring, bleaching…

Which results will AIRO® deliver?

- Softness, volume, drape (AIRO® HAND)

- Lamb skin effect on polar fleece

- Clean surface and inhibition of pilling formation*

- Opening of the chenille and three-dimensionality on jacquards

- Swelling and volume on velvet, corduroy, and pile fabric in general

- Dimensional stability on knitted and stretch fabrics

- Perfect preparation of lyocell*

- Relaxation, increase in elasticity, resilience, and “sewability”

- Délavé effect, colour reduction, vintage effect*

- Hand breaking on rigid fabric or laminated materials

- Casual look and wrinkled effect

- Softness and uniformity of the surface on printed cloths

- Peachy hand on emerized and brushed surfaces

- Grain-enhancement and natural/aged look on synthetic leather

- Touch enhancements such as “paper hand” or “gummy hand”

- Compaction and light felting on woollen fabric

- Opalescence and frosted effect*

- …and many others!

(*) only on AIRO® machines with washing capabilities

AIRO® hand label certifies the original AIRO® effect of the fabric finished in a Biancalani machine.

Technical Specifications

AIRO® 2 | AIRO® 2 SL | AIRO® 4 | AIRO® 4 SL | |

|---|---|---|---|---|

Number of channels | 2 | 2 | 4 | 4 |

Drying & softening treatments | ✓ | ✓ | ✓ | ✓ |

Steam treatments (i.e. polar fleece) | ✓ | ✓ | ✓ | ✓ |

Wet treatments (i.e. enzyme washing) | ✓ | / | ✓ | / |

Loading capacity | 1.200 m | 1.200 m | 2.400 m | 2.400 m |

Fabric treatment speed | 30-1.000 m/min | |||

Maximum treatment temperature Air heating with steam | 150°C | |||

Air heating with gas or diathermic oil | 170°C | |||

Average evaporation capacity | 175 kg/h | 175 kg/h | 350 kg/h | 350 kg/h |

Maximum water temperature | 70°C | / | 70°C | / |

Tank capacity for chemical products | 600 L | / | 600 L | / |

Installed electrical power | 92 kW | 72 kW | 169 kW | 141 kW |

Average electrical power absorption | 44 kW | 40 kW | 77 kW | 70 kW |

Installed thermal power for air | 400 kW | 350 kW | 800 kW | 700 kW |

Installed thermal power for water | 520 kW | / | 810 kW | / |

Dimensions (W x L x H) | 5.100 x 8.350 x | 3.950 x 8.600 x | 6.850 x 8.600 x | 5.500 x 9150 x |

*The data shown can be changed at any time without prior notice due to product modification and improvement | ||||

Download brochure

CONTACT & SUPPORT

Write us to get more information or to request a test on your fabrics.

WHY CHOOSE US

At Biancalani we do a lot more for you than just building machines. We listen to your advice and desires and make it easy for you to reach your goals offering you our past as a present: we strive to be part of your future.