Man-made cellulosic fibers are totally back in fashion next year, as stated by AW 23/24 fashion forecast. Lyocell, modal, cupro and viscose will be the textile version of a tripartite trend boasting freedom, change and care as its pillars.

Lyocell, Modal, Cupro, Viscose

Lyocell, Modal, Cupro, ViscoseAfter the tumult started in 2020 and in an era of uncertainty, both companies and consumers need a certain amount of freedom as they move forward. As per textiles, freedom will come in a sort of fluidity and variation of materials. As per change, it will all be about the ability of companies to quickly adapt to new ways of designing, making and selling. Besides, as inclusivity and sustainability are long-term trends that don’t seem to be fading away and as consumers look for items bringing a soothing and healing sense of protection to their everyday life, care for fibers will absolutely be a must for the textile world.

Now, with that said, let’s get to how man-made cellulosic fibers can be treated in order to reflect these textile forecasts. As there is nothing accidental or improvised about the textile business, to have expertise in the field of man-made cellulosic fibers can obviously make the difference. Since decades, Biancalani Textile Machinery has been collaborating with some of the biggest producers of cellulosic fibers. Biancalani R&D has been working closely with them in order to develop treatments that have become fundamentals and optimizers of the production processes.

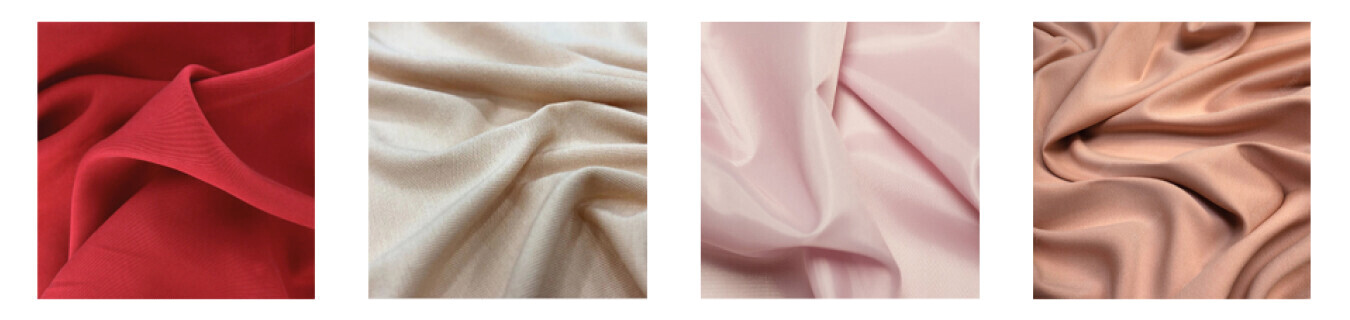

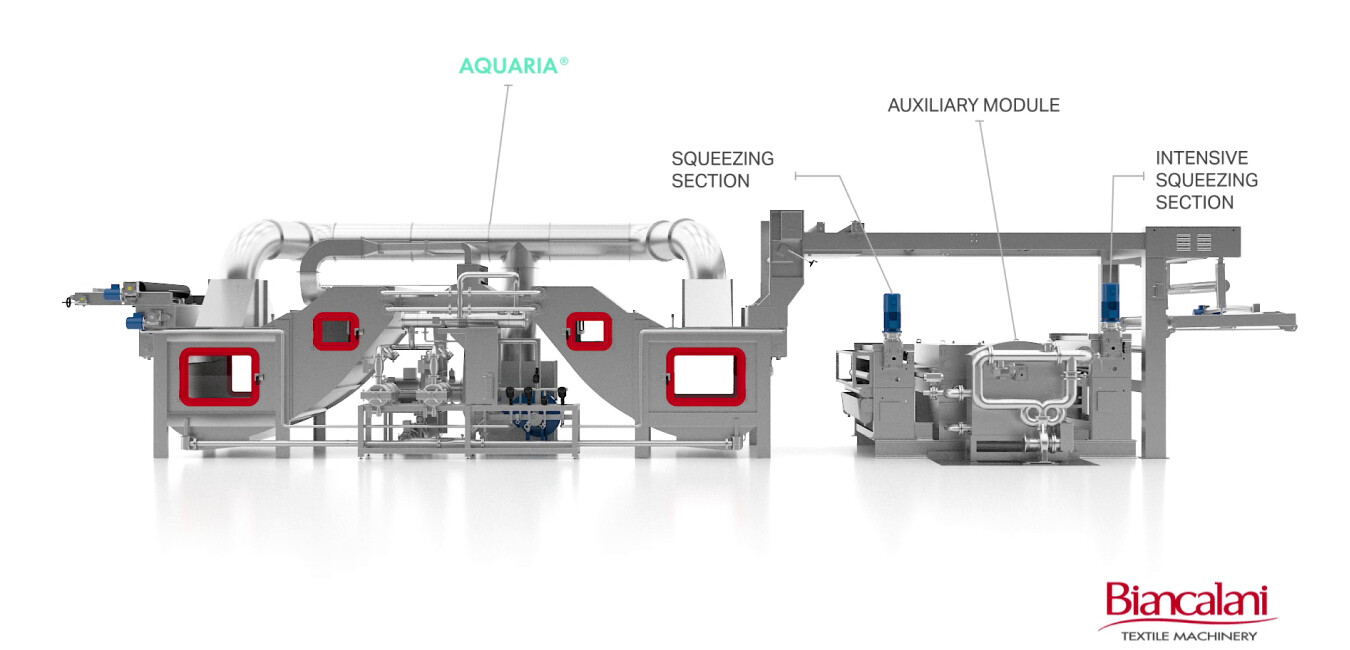

The same tripartite nature is what characterizes the ideal solutions for man-made cellulosic fibers finishing: AQUARIA®, AIRO® and AIRO®24 by Biancalani. Let’s start from the ultimate details that make AQUARIA® the ideal option for textile washing: a combination of long dwelling time and mechanical action you’ve never seen before, in a space so much smaller than the already existing lines. Fashion trends are precisely hinting at special washing process for equally special final results and effects. The washing and drying processes characterized by a strong mechanical action are what make AIRO® the all-in-one textile machine to perform special treatments like fibrillation, defibrillation and enzymes, already well-known and iconic. That is the latest, major trend for next year and Biancalani has already tested those treatments profusely. Finally, the ultimate performances are reached precisely by one of the evolution of AIRO®, AIRO®24, the original dryer for continuous and open-width tumbling treatments with high production capacity and real flexibility. A certainty for any cellulosic or woven fiber.

CONTACT & SUPPORT

Write us to get more information or to request a test on your fabrics.

WHY CHOOSE US

At Biancalani we do a lot more for you than just building machines. We listen to your advice and desires and make it easy for you to reach your goals offering you our past as a present: we strive to be part of your future.